GASOLINE FUEL SYSTEMS

Safety standards for gasoline fuel systems on recreational boats.

Electric Propulsion: For imformation on Electric Propulsion Systems see https;/newboatbuilders.com/pages/electricity17_propulsion.hmtl

Page 1 of 2

Reasons for Fuel Systems Standards. Why is it required?

A page about Marine Engines

The EPA regulations cited below are now in effect. They became effective January 1, 2012 and all boat builders and boat importers must comply with them.

Ethanol and Blended Fuels: In recent years the US EPA has required use of Ethanol blends in gasoline. E10 (10% Ethanol) was the standard, but in 2010 and 2011 the EPA began looking at the use of E15. The marine industry raised strong objections to this and as of 2012 E15 use is limited to road vehicles produced after 2007. It is not recommended for use in marine engines. Here are some references:

Survey Of Published Data And Reports On Blended Fuels In Marine Applications: US Coast Guard.

http://www.nmma.org/assets/cabinets/Cabinet213/USCGSurveyReporton

BlendedFuels.pdf

Hottopics: The latest on Ethanol And New Research On Isobutanol

USCG and EPA Guidline for fuel systems

Warning: I am only going to very briefly cover the basics here. There are requirements in the Federal Regulations and in ABYC standards that are not included here! I will only hit the high points. Contact ABYC and the Coast Guard to get the latest standards for fuel systems. Read the Federal Regulation 33 CFR 183.501-183.590. Federal regulations for recreational boats apply only to gasoline, but I have included notes when the rules for gasoline differ from the ABYC standards for diesel. ABYC has standards for both permanently installed gasoline fuel systems. and portable fuel systems.

Diesel Fuel Systems: The USCG does not regulate diesel fuel systems for recreational boats. However, ABYC does have a standard for Diesel Fuel Systems in ABYC H-33. Contact ABYC (https://www.abycinc.org) for a current copy. There are also ISO ( ISO 10088 can be obtained through ABYC) and Canadian Standards for Diesel Fuel Systems.

Note: For Boats with a fuel system that has the fuel pump in the tank, see Exemptions and Equivalency. You may be required to comply with ABYC H-24, Gasoline Fuel Systems for pump in tank fuel systems. See Fuel Systems Page 2

The Federal fuel system safety regulations in 33 CFR 183.501-183.590 apply to: Recreational Boats with permanently installed inboard gasoline engines for;

Propulsion

Generators

Auxiliary Equipment

This does not apply to:

Outboards:

Portable Equipment: (portable means it can be removed without using tools)

Although you aren't required to follow the Federal fuel system regulations on outboard powered boats, you should use them anyway. Better yet, use the ABYC standard which is more comprehensive than the Federal regulation. ABYC standard H-24 Gasoline Fuel Systems applies to both inboard and outboard powered boats with permanently installed fuel systems. If you ever get dragged into court, the complainants attorney will ask you. "Do you meet ABYC standards?" If you decide to use portable fuel tanks, ABYC has a standard, H-25 Portable Gasoline Fuel Systems, for boats with portable fuel tanks. They also have a standard for diesel fuel; H-33 Diesel Fuel Systems.

FUEL TANKS

I strongly recommend that anyone building boats with permanently installed gasoline tanks not build their own tanks. The reason is simple. You have to certify that whatever you put in this boat meets Federal Regulations. Fuel tanks have to meet a whole raft of rules, both USCG and US EPA, and unless you are setup to test them it's better to just buy them from someone who has already tested and certified the tank.

The same logic applies in other countries that use the Recreational Craft Directive, or the ISO standards. It is much easier for a boat manufacturer to buy tanks from a tank manufacturer who certifies that the tanks meet the regulations that apply in that country, than it is to build your own and go through the lengthy and expensive certification process.

Here's a list of the USCG tests that tanks have to meet. See 33 CFR 183.501-183.590

The 2 ½ minute fire test: Under very specific conditions the tank has to survive a fire for 2 ½ minutes. The test setup for this is not cheap and only a few test labs have one and know how to perform the test.

Slosh Test:

Pressure Impulse Test:

Static Pressure Test:

The tank must be capable of passing all of these tests. If it passes the Static Pressure test it must have a label that says; "This tank has been tested under 33 CFR 183.580" which means it has passed the static pressure test. There is more information that needs to be on this label. See labels

Also, if you are planning to put the tank in the forward half of the boat it has to meet additional requirements. Tanks that don't meet those requirements have to have a label saying "Must be installed aft of the boat's half length."

Gasoline tanks cannot be integral with the hull. That means that the hull cannot form one side (or more ) of the tank. Tanks must be separate from the boat structure and cannot support a structure or deck. Some boat builders do use integral tanks but only on diesel powered boats. Diesel fuel tanks may be integral with the hull.

Additionally, plastic (cross-linked polyethyelene, roto molded) tanks have to meet EPA requirements for evaporative emissions and be labeled by the tank manufacturer.

The best practice is to buy a tank from a tank supplier that certifies the tanks.

Some other considerations. Basically there are two kinds of tanks commonly used in recreational boats, aluminum and plastic. Both have distinct advantages. Some people swear by aluminum, others swear at it. The same is true for plastic. I prefer plastic. Plastic tanks don't corrode. But the choice is yours to make. Tanks are occasionally made out of other materials such as steel, stainless steel, monel and so forth. If you want to use materials other than aluminum or plastic, you will probably have to have the tank specially made. No matter what material they are made out of they all have to meet the same requirements for strength and fire resistance.

Some builders want to build tanks out of fiberglass reinforced plastic (FRP). This is common practice for diesel tanks but not advisable for gasoline tanks. It is not prohibited, if they meet all the other requirements for gasoline tanks. But, there have been serious problems with FRP gasoline tanks leaking, primarily due to high levels of ethanol (ethyl alcohol) in the fuel. I would strongly recommend you do not make gasoline tanks out of FRP.

Prohibited Materials:

Ternplate: (Sheet steel, coated with a lead-tin alloy. An alloy of lead containing tin (10-20 per cent) and antimony (1.5-2 per cent.)

Black Iron or Carbon Steel: Unless galvanized on the inside and outside.

Ferrous materials encased in foam: If you want to enclose a tank in foam the tank cannot be a tank made of a ferrous (iron or steel) material.

To see all of the ABYC standards for tanks call the American Boat and Yacht Council , (410-990-4460) and get a copy of H-24 Gasoline Fuel Systems, or H-33 Diesel Fuel Systems.

The rules for plastic fuel tanks have changed. The US Environmental Protection Agency (EPA) has published evaporative emission regulations for fuel systems on recreational boats. When purchasing plastic tanks be sure to ask your supplier if they meet the EPA regulations. |

Here are some links to explain the Evaporative Emissions Regulations from the EPA.

USCG and EPA Guidline for fuel systems

http://www.uscgboating.org/assets/1/AssetManager/ABYC.1002.01.pdf

EPA Documents on Evaporative Emissions Regs

Fuel Tanks An article I wrote for Pacific Yachting Magazine Published January 2009 (in PDF Format)

Fuel Tank openings: Any opening in gasoline fuel tanks must be on the topmost surface of the tank. The fuel inlet, the fuel tank vent, the opening for the level gauge and the opening for the pick up must all be on the topmost surface of the tank.

Prohibited openings: Drains are not allowed on gasoline tanks. Sight gauges are not allowed.

Diesel tanks are allowed to have openings below the top of the tank such as a drain, or sight gauges.

Content Continues After Ad

Foaming in Fuel Tanks: (encasing the tank in plastic foam)

Some builders believe in encasing a metal tank in foam. They think it is a good way to protect it and support it.

Not A good Practice: I believe that foaming in a tank is a death sentence for a metal tank. I could go on at length about this (and on occasions I have) but the surest way to trap moisture against a tank and cause it to corrode is to encase the tank in foam. This is why the USCG made the installation of fuel tanks encased in foam so difficult. Sec. 183.516 Cellular plastic used to encase fuel tanks. Put simply, the bond between the tank and the foam breaks and moisture collects between the foam and the tank. It has no way out and does not evaporate. The tank corrodes.

ABYC Standard H-24 Gasoline Fuel Systems says the same thing as the USCG regulation. However, there are boat builders who believe that foaming in tanks is the way to do it. This is a controversial subject and there has been a lot of debate about it over the years.

Sec. 183.552 Plastic encased fuel tanks: Installation.

(a) Each fuel tank encased in cellular plastic foam or in fiber reinforced plastic must have the connections, fittings, and labels accessible for inspection and maintenance.

(b) If a metallic fuel tank is encased in cellular plastic or in fiber reinforced plastic, water must not collect between the plastic and the surface of the tank or be held against the tank by capillary action.

(c) If the plastic is bonded to the surface of a metallic fuel tank, the adhesive strength of the metal to the plastic bond must exceed the cohesive strength of the plastic.

I believe that foaming a metal tank in place is a death sentence for the tank. Why? Because the foam traps moisture between the foam and the tank. It is that simple. Some builders like to foam tanks in place. It is simple, cushions the tank against impact, and they don't have to build a complicated mounting system for the tank. However, consider the consequences.

The US Coast Guard requires that if you foam a tank in place the strength of the bond of the foam to the tank must be stronger than the foam itself. In other words, a shearing force would break the foam before breaking the bond. In practice this is very difficult to achieve. What happens in reality is that after repeated slamming of the hull, and vibrations from the engine, the bond breaks. This creates a gap between the tank and the foam, and moisture gets trapped around and under the tank. Further, the requirements for tank installation are, no moisture can be trapped on the top of the tank, and the fuel fittings must be accessible. This means if you foam the tank you must leave an area clear of foam around the fittings, or not allow any foam above the top of the tank. Otherwise any moisture on top of the tank gets trapped there by the foam. In practice the above requirements are rarely achieved and the tank corrodes long before its normal life span.

Also consider aluminum tanks. Aluminum tanks are rarely painted because they have a natural aluminum oxide coating that is formed by exposing aluminum to air. This oxide protects them from corrosion. So aluminum tanks should always be mounted with space on all sides and the bottom. To paint aluminum or to bond foam to it, you must remove the aluminum oxide. You are removing the very thing that protects the tank from corrosion.

Plastic tanks on the other hand do not need coatings or paint. They need to be installed so that they will expand a little when first filled. Foam would not allow this expansion. Additionally foam will not adhere well to polyethylene plastic, so it is impractical to foam in a plastic tank.

FUEL SYSTEMS:

Vents: Fuel tanks have to be vented. The vent itself has to either have a flame arrestor that can be cleaned, or be designed in a way to prevent a flame front from igniting the fumes in the vent. There are a lot of different brands of fuel vent fittings on the market that accomplish this. Some times the vent line itself can be a flame arrestor. This depends on the design of the vent.

The US EPA rules may require charcoal filters on vent lines. Check with the USCG or ABYC. (The links below are not an endorsement of Perko, Attwood or BlueSkies. It only illustrates the system with a charcoal filter.)

In addition canisters must not get water or liquid fuel in them because it ruins the contents and makes them unusable. So there must be

some means in the vent line to prevent water intrusion. The following items are methods that can be used. There are other solutions.

Perko's Water Deflector vents

This vent must not allow gasoline that might spill from the vent when someone overfills the tank, to spill into the boat. However, it is also illegal to spill fuel into the environment. So, think about it. There are several manufacturers that make combined fuel fill and vent fittings that do just that.

Fuel hose must now meet much stricter standards for evaporative emissions. Look for hose labeled USCG Type A1-15, USCG Type B1-15. This means it meets the new EPA standard.

Fuel Hose: When fuel hose is used it must be either USCG Type A1-15, USCG Type B1-15. Where you use it determines what type you use.

From the fuel inlet on the engine (usually the fuel pump) to the carburetor you must use Type A1-15.

Each fuel vent line or fill line must be USCG Type A1-15 and the line from the fuel tank to the engine inlet must be type A1-15;

UNLESS:

if no more than five ounces of fuel is discharged in 2 1/2 minutes when:

(A) The hose is severed at the point where maximum drainage of fuel would occur,

(B) The boat is in its static floating position, and

(C) The fuel system is filled to the capacity market on the tank label.

Then you may use Type B1-15.

As a practical matter, few boat builders want to have to stock two types of hose, so most buy only Type A1 and use it everywhere. This is fine. Just be sure that you put in your owner's manual that the hose from the fuel pump to the carburetor and the vent and fill hose must be TYPE A1-15.

So what is the difference between A1, and B1. USCG Type A hose has to pass the 2 ½ minute fire test, B does not. The theory is the A is under more pressure than B, and being on the engine is exposed to more danger of fire than B. Since B is between the pump and the tank, if a leak occurs, the pressure rapidly drops to zero and the pump just sucks air, stopping the engine. Fuel doesn't get sprayed all over the place. The fuel line between the fuel pump and the carburetor, or fuel rail, is under pressure and if a leak develops, fuel will be sprayed around the hot engine. So there is a greater risk of fire. This hose must be A1-15 which is fire resistant. In addition, A1 hose is required when the hose always has fuel in it. Hose that only has fuel in it briefly, such as the fuel fill hose may be B1.

You do not have to use hose! You can use metallic lines. Some manufacturers do. For example, Mercury Marine inboard engines come with steel fuel line from the fuel pump to the carburetor. Metal lines do not allow vapor to escape through the fuel line walls.

Metallic fuel Lines: If you use metallic fuel lines, the ones that run from the fuel tank to the fuel inlet on the engine must be one of the following; seamless annealed copper, nickel-copper, or copper-nickel. From the fuel pump to the carburetor they can be any metal you want to use. Beware. You could set up a galvanic couple and the tube will be eaten away like powder. Choose carefully if you use metal fuel line from the pump to the carburetor. Do not use copper tubing. Pure copper is very subject to galvanic corrosion and cracking from vibration.

Fuel System Myths:

Belief: "Loop's in fuel lines are a Coast Guard/ABYC violation. Fuel must flow downhill to the tank without any traps as it can be a fire hazard if the boat burns."

Not True: This is a direct quote from a boating forum. The writer was speaking about the fuel tank vent line. Loops are not prohibited by the USCG or ABYC. The vent line needs a means of preventing water from entering the system, per ABYC.

ABYC H-24.14.6

"The tank vent system shall prevent the intake of water when tested to section H-24.18 Installation tests"

A loop is one means of doing this but it is not prohibited.

The USCG fuel regulations doesn't even mention this. See 33 CR 183.501

Belief: The Coast Guard (or ABYC) bans Stainless Steel tanks:

Not true: The only tank material that is banned is ternplate, a tin-lead metal that is very prone to corrosion. Stainless tanks are permitted. However, they are very prone to a condition called crevice corrosion, so ABYC recommends they be 20 gallons or less with domed ends. This minimizes the welds where they are most subject to corrosion. They should be mounted where they will be dry and can be inspected on all sides. Only 316L or 317L stainless should be used. As with all the above, tank regulations are manufacturer requirements.

Belief: "Look at ABYC H-24 Gasoline Fuel Systems. Gasoline fuel tanks may not be installed in engine compartments."

Not True: ABYC does not prohibit fuel tanks from being installed in engine compartments. This is why ignition protection, ventilation, and fuel systems regulations exist. Fuel tanks are frequently located close or in the same compartment as the engine.

Anti-Siphon:

The fuel line on a boat must run uphill, or else you have to have an anti-siphon device. An Anti-Siphon valve is that annoying little valve that most builders put at the tank outlet, that seems to get clogged at the most inconvenient times. So, if the top of the fuel tank is higher than the inlet on your fuel pump you have to put anti-siphon in the system. This is because the possibility exists that your entire fuel tank could siphon out into your carburetor, and fill up your manifold, and ruin your whole day! So, the solution is obvious. If you don't want this nasty little gadget in the fuel line, put the tank lower than the engine fuel inlet. But, also make sure none of the fuel line between the tank and the fuel inlet on the engine dips below the level of the tank top.

Some people believe your powerboat must have an Anti-Siphon valve:

Not True. 33 CFR 183.568 The US Coast Guard requires an anti-siphon valve on inboard powered boats with permanently installed fuel systems, if the fuel tank is higher than the fuel inlet on the engine. That means if the fuel line runs down hill from the tank to the engine, you need an anti-siphon valve. If it runs uphill, that is the fuel inlet on the engine is higher than the tank, then you don’t need one. These little valves cause a lot of problems and are always getting clogged by junk in the fuel. If you don’t need it, get rid of it. They are not required on outboard boats. ABYC standards do require them on outboards with permanently installed fuel systems, but only if the fuel system can siphon itself, which is the same as the USCG requirement for inboards.

System Pressure Test: The entire fuel system must be pressure tested to insure there are no leaks. You have to test the system at least at three PSI, unless you have a long deep system. Then it must be 1 ½ times the greatest pressure in the lowest part of the system. For most boats three PSI will do.

Grounding: All metallic components of the fuel system that are in contact with fuel must be electrically grounded to prevent a static discharge from causing a fire or explosion.

Recent events have caused the boating industry to examine the policy regarding the bonding of plastic body fuel fills with metallic caps and retaining chains. Existing USCG & ABYC policy states that the bonding of these components is voluntary. A study by IMANNA Laboratories has shown that connecting the metallic retaining chain and cap of a plastic body fuel fill assembly to a boats bonding system may result in electrostatic discharge from a land-based fuel pump nozzle to the metallic components of the assembly when the boat is not in the water. This condition does not exist when the boat is in the water due to the equalizations of the ground potentials between the fuel pump nozzle and the boats bonding system. It is recommended by ABYC and the USCG that new and existing installations of this type of fuel fill assembly DO NOT INCLUDE any attachment to the boats bonding system. Existing connections should be removed from the point of connection to the boats bonding system to the fuel fill assembly. Removal of the metallic components of the assembly is not necessary; however, the U.S. Coast Guard and ABYC still require that METALLIC body fuel fills be bonded. For further information contact: ABYC (410) 956-1050 info@abycinc.org |

|

A typical fuel tank installation showing fill (red hose), vent and fuel line to engine (center). The fitting in the upper right corner is the fuel gauge sender. |

|

Type A1 Fuel Hose (Blue Stripe) and Type A2 Fuel Hose (red Stripe) (A2 no longer used) |

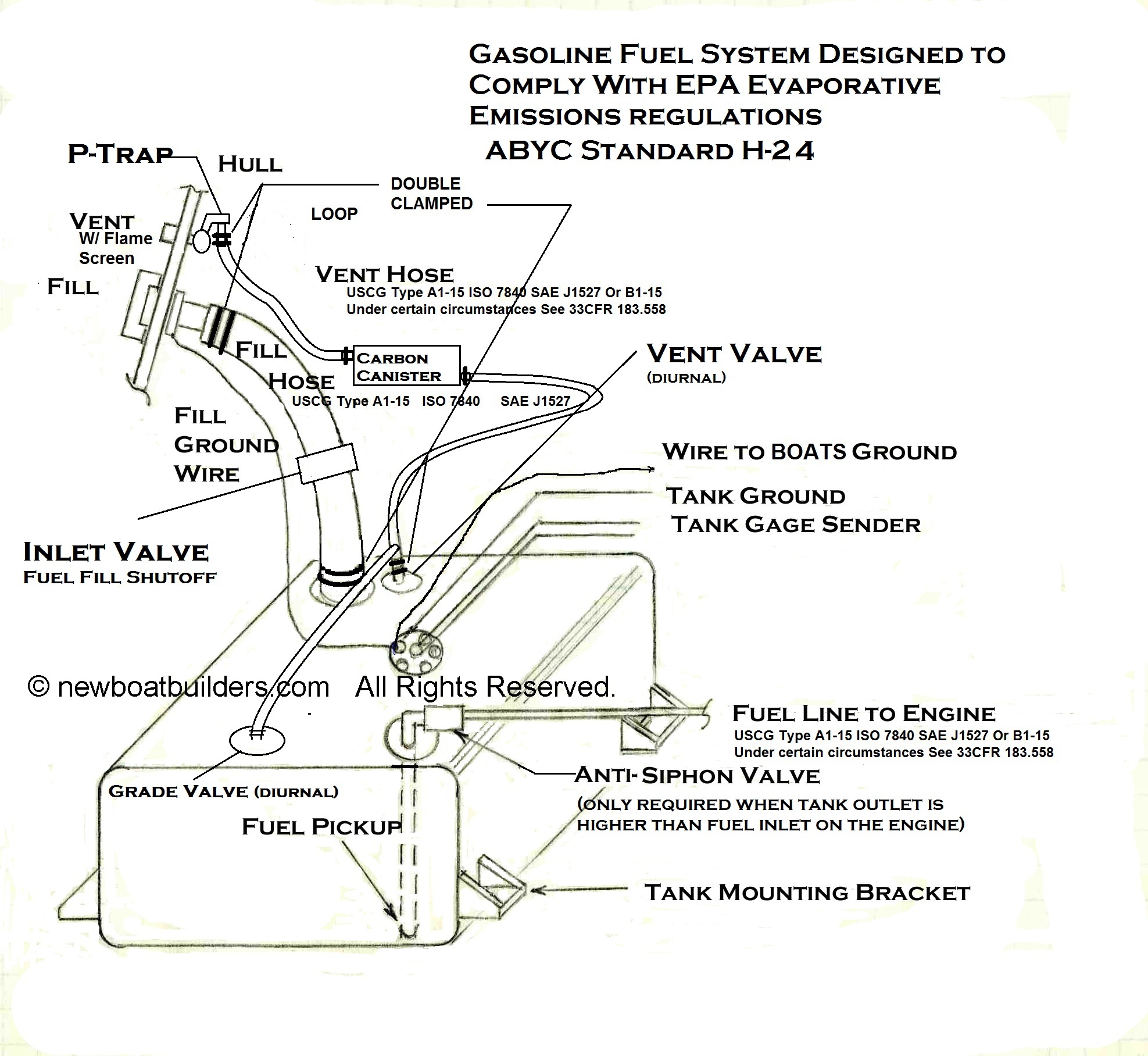

A diagram of a typical fuel tank setup for a single tank - After January 1, 2012 (Click on the image for full size), The page will also show a typical fuel tank prior to January 1, 2012. References: 33 CFR Subpart J: Fuel Systems USA Recreational Boat Fuel System Regulations TP 1332: CONSTRUCTION STANDARDS FOR SMALL VESSELS Section 7 Fuel Systems Canada Standards for small craft. |

|

For Gasoline Fuel Systems on Recreational Boats Made or Imported into the United States After January 1, 2012, EPA Compliant Fuel System See ABYC Standard H-24 Gasoline Fuel Systems Moeller Marine Products fuel system design, regulations simplified. |

Inspected Vessels:

For manufacturers/builders building small passenger vessels that are inspected and certified by the US Coast Guard, there are regulations for their fuel systems different than those for recreational boats.

46 CFR Subchapter T Part 182 Machinery Installations Subpart D: Passenger Vessels under 100 Gross Tons. USA Fuel System Standards for Commercial Small Passenger Vessels. Under 100 Gross tons.

Why are there so many requirements for fuel systems?

Gasoline is extremely dangerous and volatile. It can go boom at the worst moments ruining your whole day! But it's no joke.

Fuel system regulations have been developed over many years, mainly by the Society of Automotive Engineers (SAE) and the National Fire Protection Association (NFPA). These have been incorporated into the ABYC standards and the US Coast Guard regulations.

Most fuel leaks occur at a fitting. So standards were developed to prevent this. Things such as double clamping a hose and using swaged fittings were made primarily to prevent leaking connections.

Hoses that were used in autos were found to be inadequate in boats. Fuel in cars does not stay in the hose very long, but in boats it can sit for months at a time. This gives the additives and the components of the gasoline itself time to attack the compound of the hose. So hoses have to be able to resist this. Alcohol in the fuel leaches out the parafins that make the hose pliable and flexible. So hose was developed that was alcohol resistant. Even so, hose should be checked periodically for cracks, stiffening, becoming very soft and mushy, and replaced.

Hoses that are exposed to sunlight have to be UV resistant as well. Hoses used for outboard engines in particular have to be UV resistant because they often are outside exposed to the sun.

Hoses used in some areas on the boat also need to be fire resistant. If a fire gets started the last thing you need is a fuel hose burning through and dumping fuel into the boat, feeding the fire. So hoses have to resist a fire for 2 1/2 minutes. Why 2 1/2 minutes? Because if your fire fighting system doesn't put out the fire in that amount of time, you probably won't put it out. It gives you time to get off the boat.

Fuel hose clamps are usually metal, although plastic ones are being used occasionally. The metal has to be corrosion resistant. So stainless clamps should be used, but all stainless! Many supposed stainless clamps are not. The little screw that tightens them is not always SS. The clamps corrode and lose their tension, loosening the connection. One of the most common causes of fires is fuel dumped in the boat when fueling up. This is because the clamps on the fuel fill hose have loosened and fuel leaks at the fitting, or the hose falls off.

Metal fuel lines also have problems. Copper in a marine environment deteriorates rather rapidly. Plus that it is subject to galvanic corrosion. So metal fuel lines have to be certain materials such as copper-nickel or nickel copper. Steel lines are also allowed. A big problem with metal fuel lines is vibration. Vibration loosens fittings, and fatigues the metal, resulting in cracks, usually at the fittings. So metal fuel lines are usually kept short, and there are short flexible lines between the metal fuel line and the engine inlet.

Other fuel system components have the same sorts of problems. Fuel pumps and filters have to be fire resistant and not leak. Fuel filters used in cars don't meet these requirements. If you get a fuel leak in a car the gas goes on the ground. In a boat it goes into the bilge. So components have to meet the same requirements as hoses and tanks.

Fuel tanks need to be of a material that doesn't easily corrode, is fire resistant, and strong enough to last with all the forces that they are subjected to. Tern plate (a lead tin compound) used to be common on cars. Unfortunately, it corrodes rapidly on boats. So tern plate is not allowed. Steel needs to be properly prepared and coated to resist corrosion. Aluminum corrodes if it is constantly wet. It also is subject to corrosion from the inside of the tank due to phase separation of the gasoline and alcohol, and alcohol's tendency to attract water. So it needs to be mounted properly to avoid corrosion. The same goes for any metal tanks. Stainless is a special problem. It too will corrode if wet, so it needs to be mounted where it can be kept dry. It is also subject to crevice corrosion, particularly at the welds. So welds need to be kept to a minimum. All of these materials have to be able to resist shock and vibration, sloshing of fuel in the tanks, and sudden accelerations in all three directions.

One question that comes up often is "why can't I put the fuel pump in or on the tank"?. This is commonly done with fuel injected systems on cars . It helps to eliminate vapor lock and insures a steady supply of fuel. However, this means that the fuel line running from the tank to the engine is under pressure. In some fuel injected systems this can be as much as 30 psi. Think what would happen if a leak developed! In a pressurized system this would result in all of the fuel in the system being sprayed into the boat. I mean all! It would empty the tank. This is one of the basic laws of physics. So, the fuel pump on a boat is required to be on or within twelve inches of the engine. That way the only line under pressure is the one from the fuel pump to the carburetor or fuel injection system. This line is usually very short, generally about a foot or maybe two on larger engines. The fuel from the tank is sucked to the engine rather than pushed. If a leak develops, the fuel just stops flowing and the engine quits. Pressurized lines and fuel systems are not allowed on boats, except for that one short line.

Why not a closed fuel system? Why does it have to be vented to the atmosphere? Doesn't this add to air pollution? Yes it does. But for the reasons cited above you don't want a pressurized system. A leak would dump all the fuel into the boat. However, the new EPA Fuel system rules do allow for up to 1 psi in the tank, fill and vent.

So the main purpose behind fuel system regulations is to prevent leaks, thereby preventing fires and explosions.

To add a complication, the US Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) have recently (since about 2001) proposed a series of regulations that would control evaporative emissions from permanently installed fuel systems, and exhaust emissions from inboard gasoline engines. The regulations would limit evaporative emissions to 15 grams per square meter of surface per 24 hour period. This is far less than the current 100 for A1 or B1 hose and 300 for A2 and B2 hose. The same requirement would apply to tanks and vent systems which have always been open to the atmosphere. Because of the safety issues surrounding pressurized systems, the EPA and CARB have agreed not to require closed systems, as are used on cars, but to require a charcoal canister in the vent that would not create back pressure and would absorb fuel vapors. Plastic tanks would also have to limit the amount of vapor permeated through the tank wall. The engine exhaust will have a catalytic converter, similar to cars but much smaller in size. Some of these regulations go into effect in 2009, and all go fully into effect in 2010. As of July 2012 all of these EPA regulations are in effect. See See the Page on environmental rules.

|

This Web site may contain copyrighted material the use of which has not always been specifically authorized by the copyright owner. I am making such material available in my efforts to advance understanding of educational, economic, and scientific issues, etc. I believe this constitutes a "fair use" of any such copyrighted material as provided for in section 107 of the US Copyright Law. In accordance with Title 17 U.S.C. Section 107, the material on this Web site is distributed without profit to those who have expressed a prior interest in receiving the included information for nonprofit educational purposes. For more information see: www.law.cornell.edu/uscode/17/107.shtml. If you wish to use copyrighted material from this Web site for purposes of your own that go beyond "fair use", you must obtain permission from the copyright owner. |